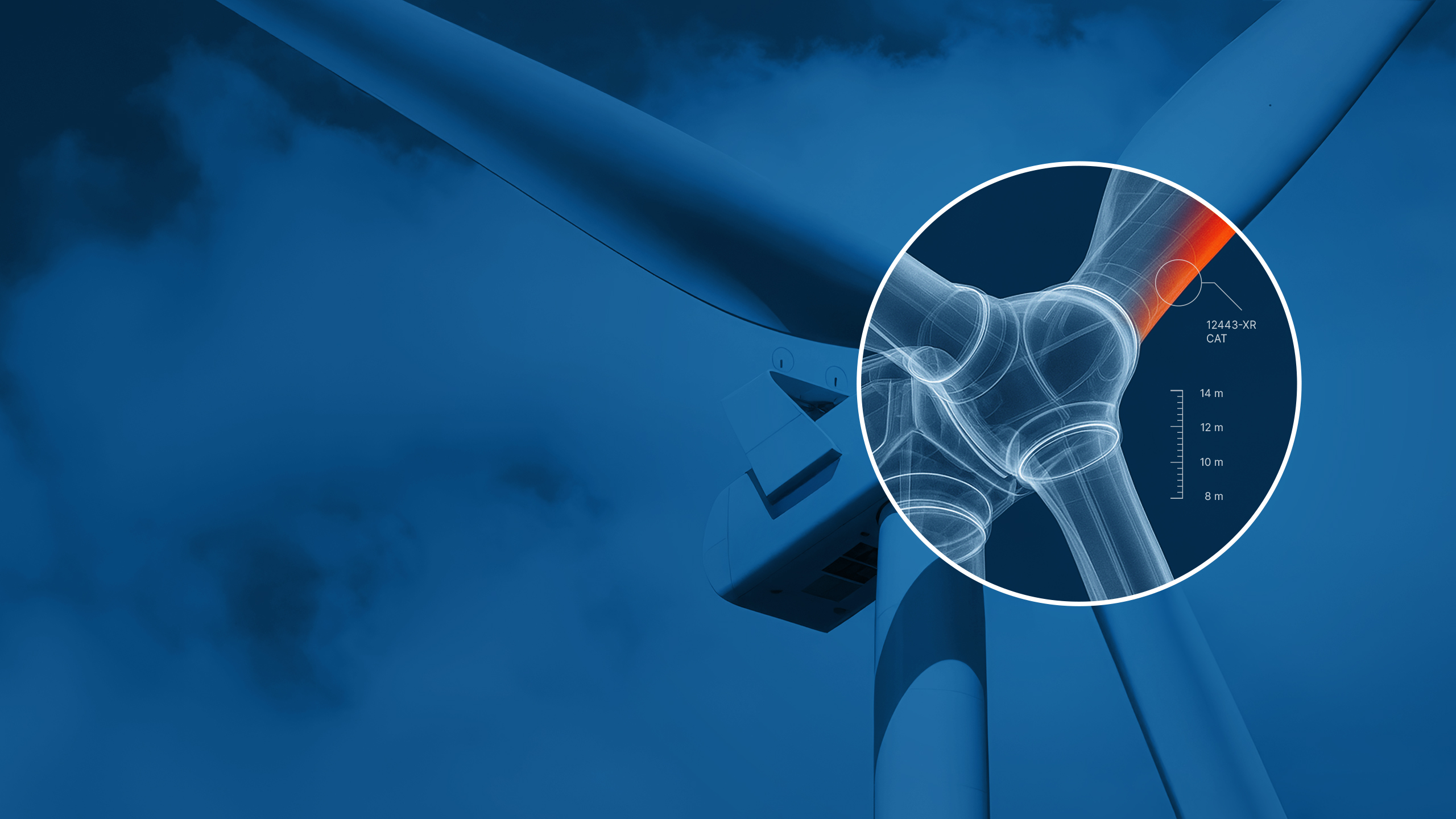

Inspections

Lightning Protection System, Visual inspections and Non-destructive testing

Explore more

Cleaning

Cleaning dirty rough blades and oil contamination from wind turbine towers

Explore more

Now officially launched – access it via the Customer Portal or request a demo profile

LoginRequest Demo

Aerones is the world leading robot-enabled wind turbine maintenance and inspections service provider. Leveraging patented robotics technology, Aerones service teams deliver faster, safer and more effective services for wind operators worldwide. The innovations that we deliver to the wind industry promote intelligent predictive maintenance of wind turbine blades and towers, helping to maximise efficiency of wind assets and lower operating costs. We serve customers that represent over 50 percent of the world’s wind power capacity, including leading operators such as NextEra, GE, Vestas, Enel and Siemens Gamesa.

Wide scope of robotic

wind turbine services

Robotics used are certified and have been tested for use with wind turbines. It's a much faster, safer and more efficient method than the traditional approach and is saving funds for wind parks globally.

Explore more

Lightning Protection System, Visual inspections and Non-destructive testing

Explore more

Cleaning dirty rough blades and oil contamination from wind turbine towers

Explore more

Robotized services offer up to 4x faster operations. Minimize downtime and reduce idle-stay significantly

Technicians operate in a safe environment from the ground

Projects are 4x shorter and with 10 times less idle stay thus are more economical than the traditional methods

Precise robotic tools allow to deliver top quality services that result in turbine efficiency boost

Aerones is constantly developing and expanding to become the trailblazer in the wind industry. Be sure to follow the news.

As a supplier, Aerones has provided us with various robotic solutions for wind turbine blade inspections and maintenance, and we've seen steady progress in both their technology and service delivery. Their technology is helping to address safety and services productivity in wind farms around the globe.

Veronica Barner Wind Energy Product Executive, GE VernovaWe had a great experience working with Aerones on our first ice-phobic coating project.

Bojan Alavanja Technical Asset Manager, Fortum, FinlandWe picked our dirtiest tower and hired Aerones to do a cleaning. They did a great job at an excellent price. The Aerones crew was professional and efficient. We look forward to working with them again.

Kevin Edwards Maintenance & Reliablility supervisor, Blue Earth RenewablesIt was a pleasure working with the Aerones team. Their technicians were highly skilled, knowledgeable and most importantly, safety conscious.

Timur Dede Total Safety Consulting, AustraliaCurrently, it is essential to robotize maintenance activities to reduce accidents, increase productivity and improve results. The potential is huge. We used Aerones’ technology in LPS inspection and drainage hole cleaning at the Red Dirt and Thunder Ranch Wind Plants, in Oklahoma (US). Aerones was tested on 14 units at Red Dirt and 17 turbines at Thunder Ranch. It was an operational and economic success.

Francisco J. Valle Wind Innovation Product Owner at Enel Green PowerAerones performed lightning conductivity test for 100 wind turbines in preperation for End of Warranty claims at our wind farm in Seymour, Texas. The robotic services have been high quality and expeditious with an average of 3 WTGs tested per day.

Anand Narayanan VP Asset Management at AREVONIn addition to the conductivity measurement, the system is also suitable for repair work as well as coatings on the leading edge of the blade, visual inspections of the blade surface and interior or for cleaning work on the turbine. We see a lot of potential in this technology. In the future, we could save both time and money.

Axel Stelzer Head of Technical Management at WPD WindmanagerI am very satisfied with the result as well as their professionalism while doing the service for us. We received detailed daily reports every day and overview final reports for each turbines once the job was done.

I was positively surprised that Aerones leading edge repair robot was able to work even in rainy weather. The only time we needed to stop was when the winds started to get too strong, however, the guys got back to work the next morning and finished the job on time.

I would definitely recommend Aerones for wind turbine blade repairs.

Remigijus Lapinskas Director, UAB “Gemba”Please use the form below to reach our business development team and receive information on services availability.