Aerones

Smart instruments for a smarter wind turbine maintenance

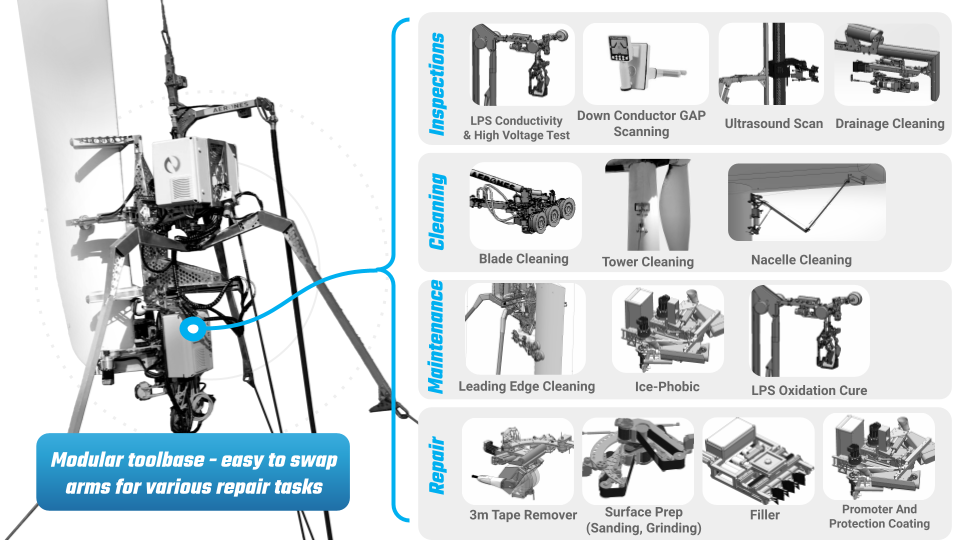

Intelligent predictive maintenance of wind turbines is the most efficient method of wind asset management. Robotic tools unlock the full potential of the wind industry by addressing potential damage before it happens. The robots operate much faster, thus reducing the downtime, costs, and carbon footprint during the services. More efficient methods of services prolong the lifetime of wind turbines. Our goal is to make wind energy more accessible for society.

Schedule a callHow it works?

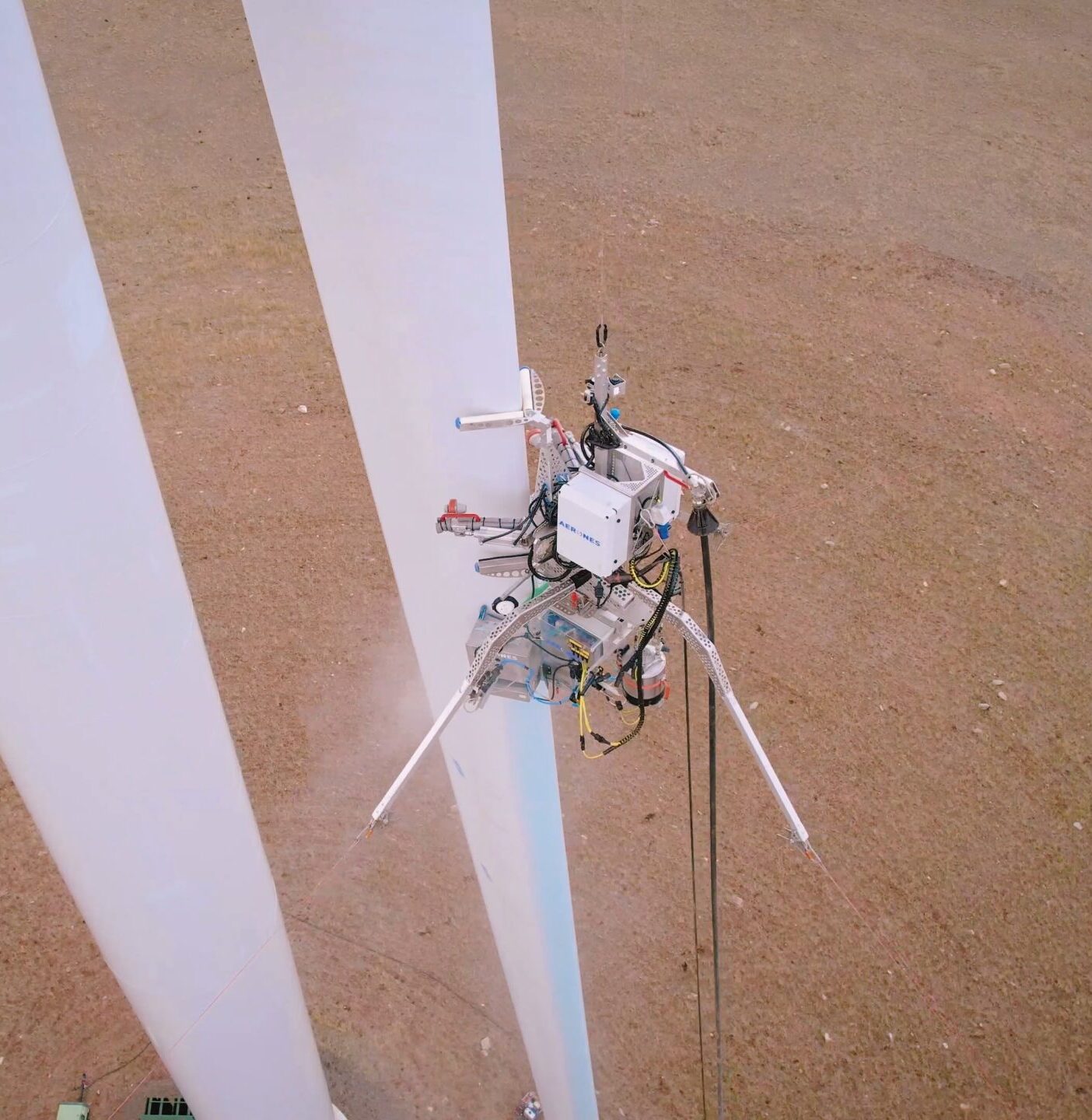

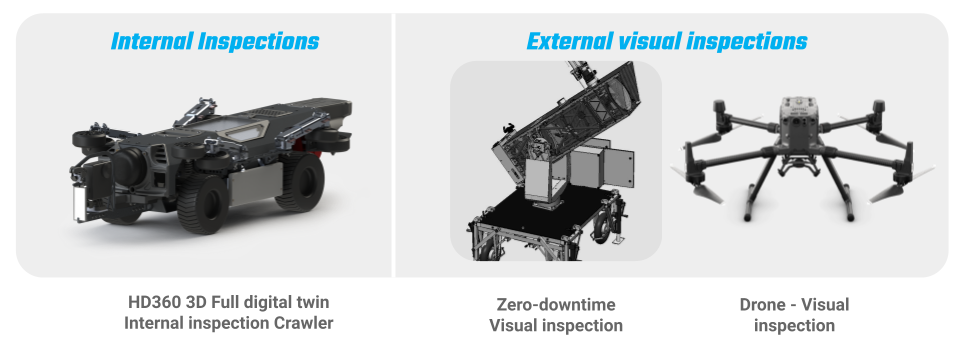

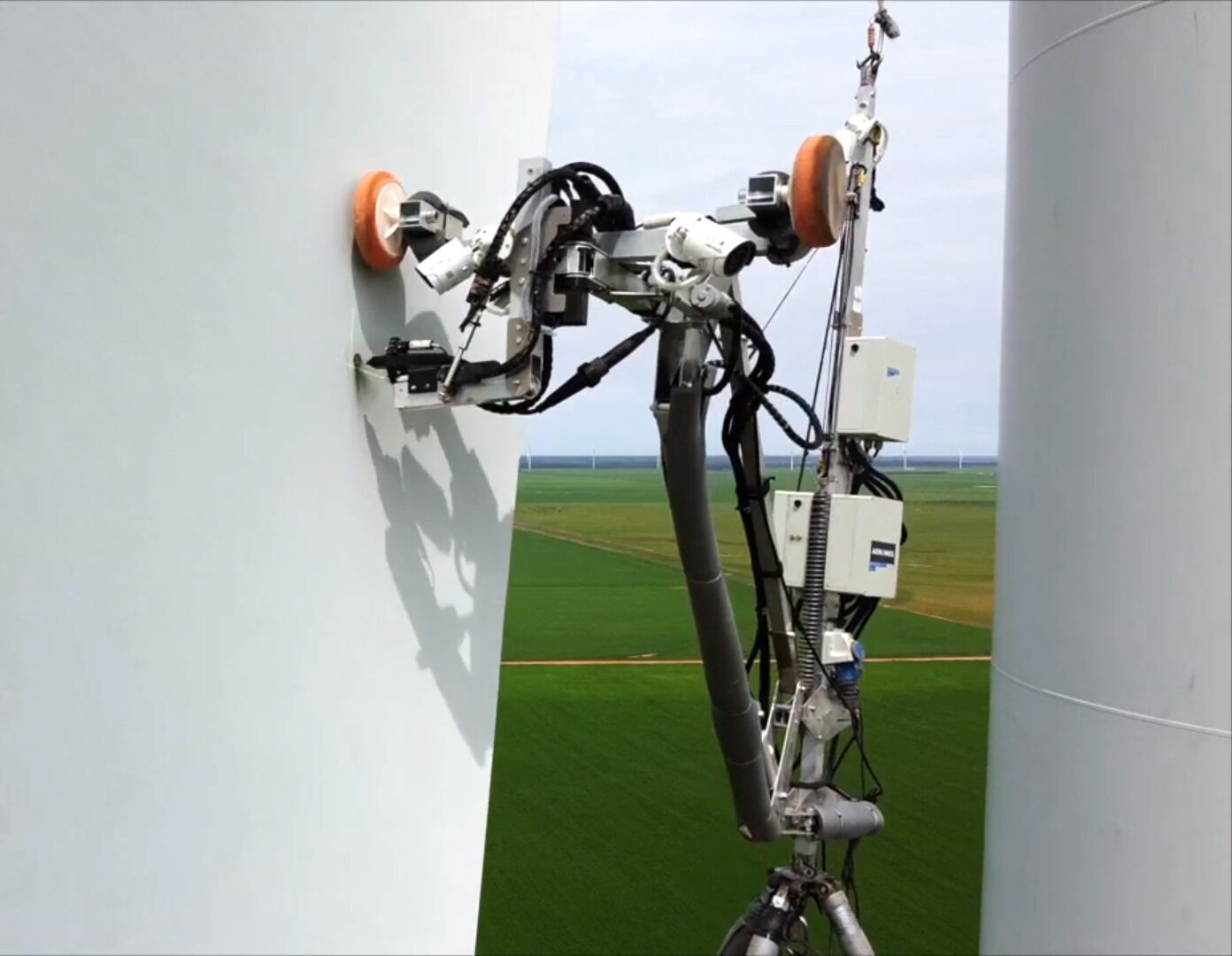

Robotic platform with a rich family of services

The unique proprietary system brings high-quality robotic services enabling our wind turbine technicians to perform inspections, cleaning, maintenance and repairs

Testimonials

Currently, it is essential to robotize maintenance activities to reduce accidents, increase productivity and improve results. The potential is huge. We used Aerones’ technology in LPS inspection and drainage hole cleaning at the Red Dirt and Thunder Ranch Wind Plants, in Oklahoma (US). Aerones was tested on 14 units at Red Dirt and 17 turbines at Thunder Ranch. It was an operational and economic success.

Francisco J. Valle Wind Innovation Product Owner at Enel Green PowerThe robotic LPS services were delivered in a high quality. The results were accepted by the insurance company to complete the obligation. Aerones demonstrated professional communication and capability to perform in challenging conditions. It has been a pleasure working with Aerones.

Heiko Voss CEO VosswindAerones performed lightning conductivity test for 100 wind turbines in preperation for End of Warranty claims at our wind farm in Seymour, Texas. The robotic sercices have been high quality and expeditious with an average of 3 WTGs tested per day.

Anand Narayanan VP Asset Management at AREVONIn addition to the conductivity measurement, the system is also suitable for repair work as well as coatings on the leading edge of the blade, visual inspections of the blade surface and interior or for cleaning work on the turbine. We see a lot of potential in this technology. In the future, we could save both time and money.

Axel Stelzer Head of Technical Management at wpd windmanagerChosen by Leading Wind Industry Players

Contact us

Schedule a presentation, receive a detailed information about the services or request a price quote