Don’t Freeze Your Assets

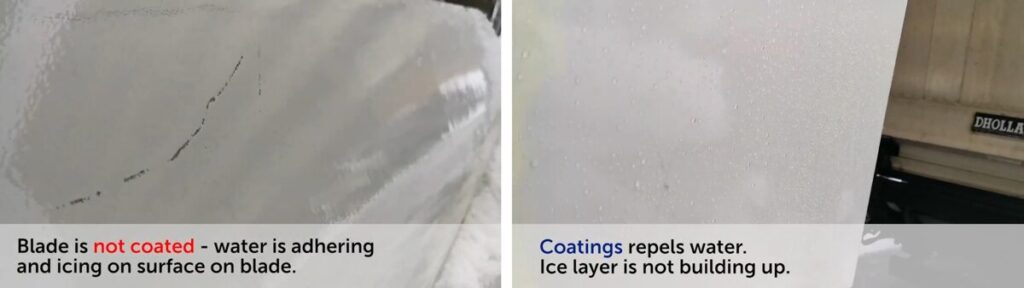

Winter is supposed to be the best season for wind power, but winter also comes with a problem: freezing weather which causes icing on wind turbine blades. Even light icing can produce enough surface roughness on wind turbine blades to reduce their aerodynamic efficiency, which reduces the amount of power they can produce. Frequent severe icing can cut a wind farm’s annual energy production by over 20% (1), costing the industry hundreds of millions of dollars.

It’s important to avoid ice accumulation on the blade and blade-heating systems are not sufficient enough, as we know from our clients and partners. What’s the best solution?

To achieve the functions of anti-icing and de-icing, coatings must have the ability to repel water droplets, delay ice nucleation from both vapor and liquid states, and finally once the ice is formed on the surface, reduce ice adhesion.

It has been another successful launch for Aerones wind turbine blade maintenance robots. With our newest robotic arm, painting and coating of wind turbine blades has become easier, faster, more precise, and cost-effective.

All of this results in a perfectly even layer of coating, minimized downtime, and continuous turbine operations during the winter season.

The process starts by cleaning the blade surface to achieve adhesion and durability of the coating. The cleaning process takes about 1 hour per blade. After the blade is clean, we continue with the coating application process.

The coating is evenly applied to ensure maximum protection. We are painting at a speed of 6 meters (20ft) per minute with our robot.

Overall, it takes approximately 10 minutes to fully coat a single wind turbine blade.

Contact Aerones today to receive a customized quote for your wind turbine blade inspection, maintenance, and repair needs.