How Robots Are Revolutionizing Wind Turbine Leading Edge Repair

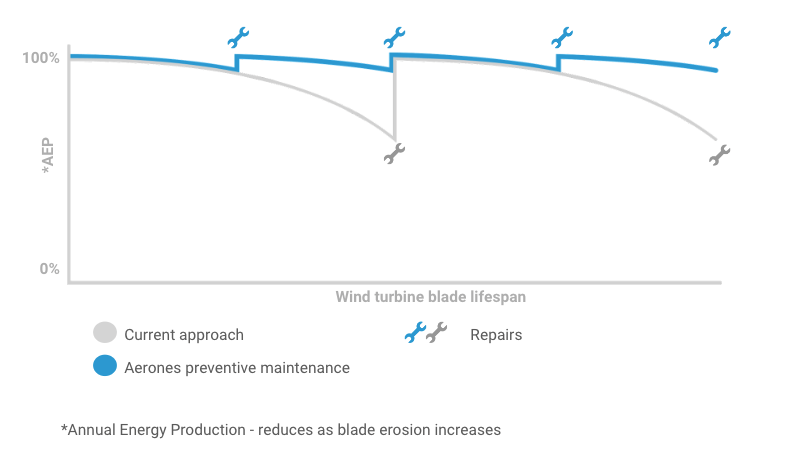

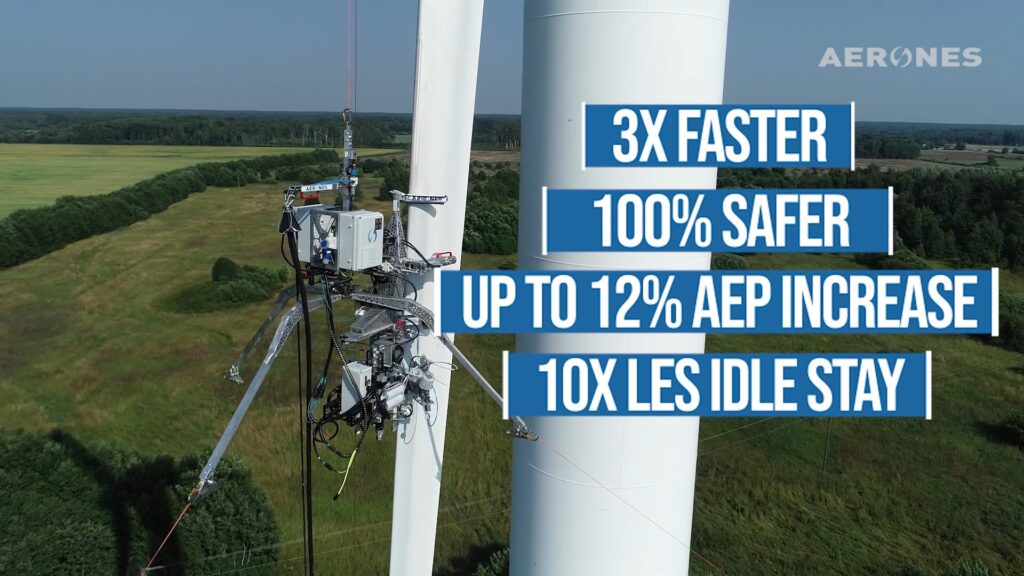

In response to the growing market demand, Aerones is proud to present the new, unique wind turbine leading edge repair robotic system. In tandem with professional technicians, robots provide the safest operations with three times faster repair service, ten times less idle stay, and an up to 12% annual energy production increase.

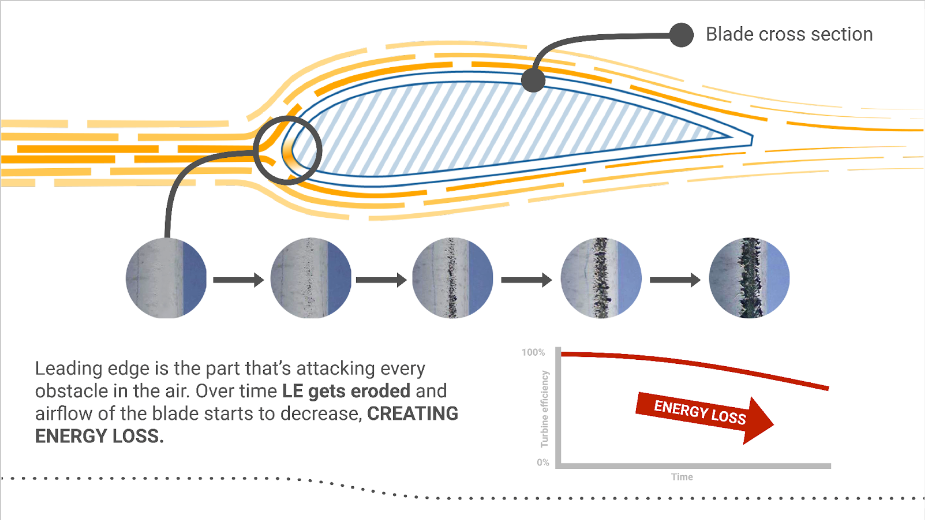

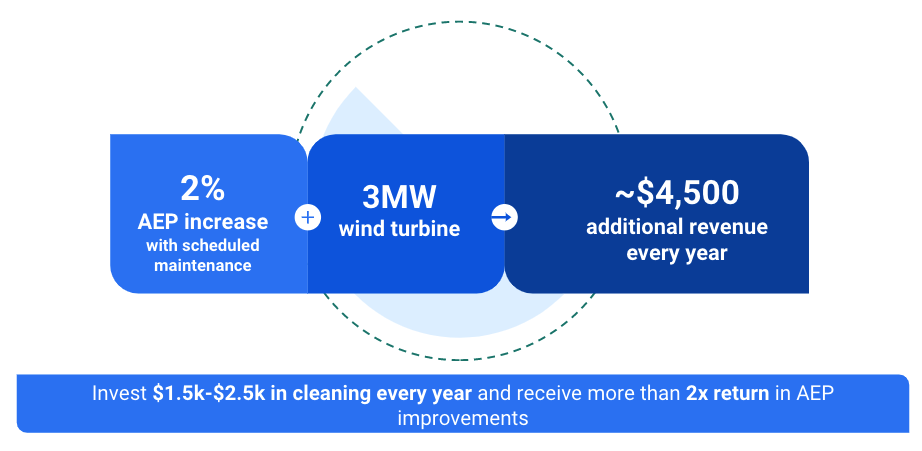

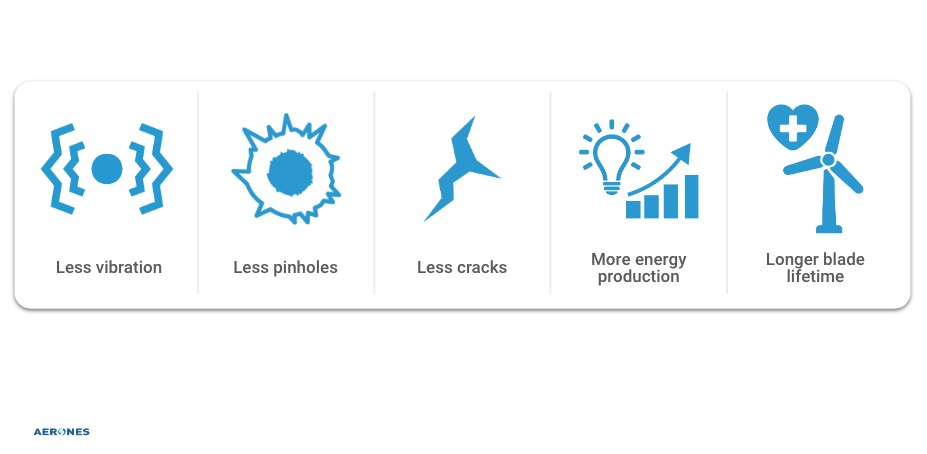

Erosion causes massive problems for wind turbine blades. The fine particulate in the air, ice, snow and rain slowly degrades the blade surface. Over time, it wears out the outer layer of the turbine blade, negatively impacting the aerodynamics of the blade. This results in less and less energy produced over the turbine’s lifetime. Therefore, regular wind turbine blade maintenance is important for the integrity of the blade structure and to prolong the lifetime of the wind turbines.

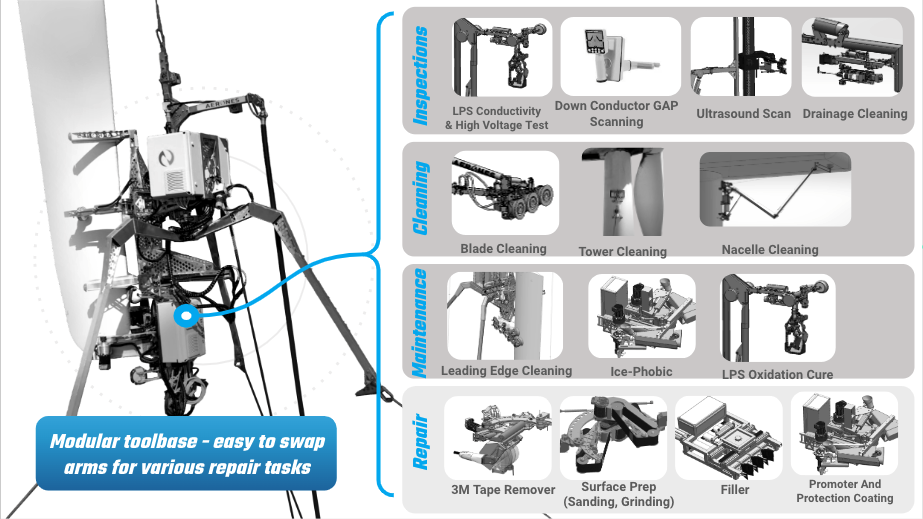

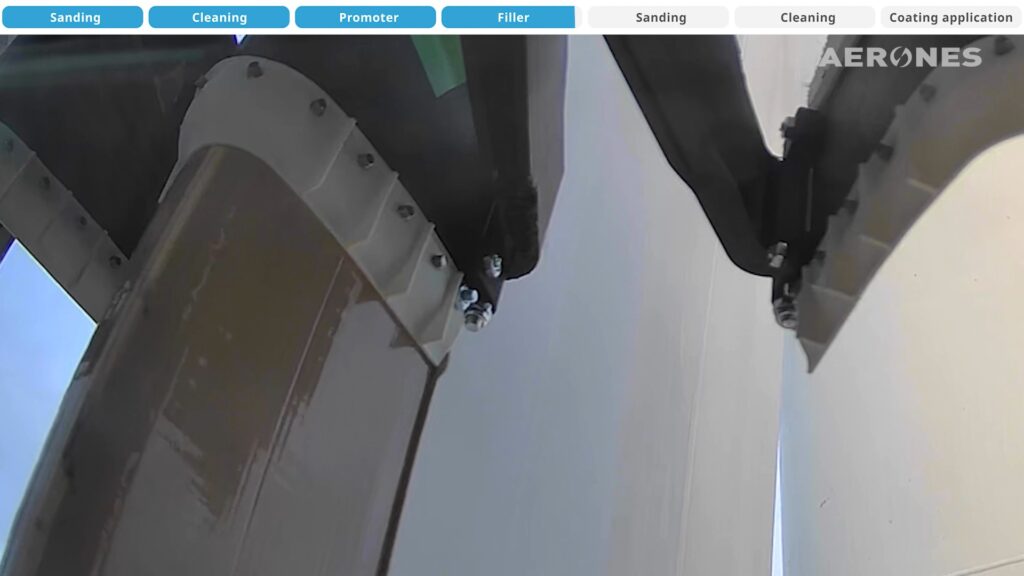

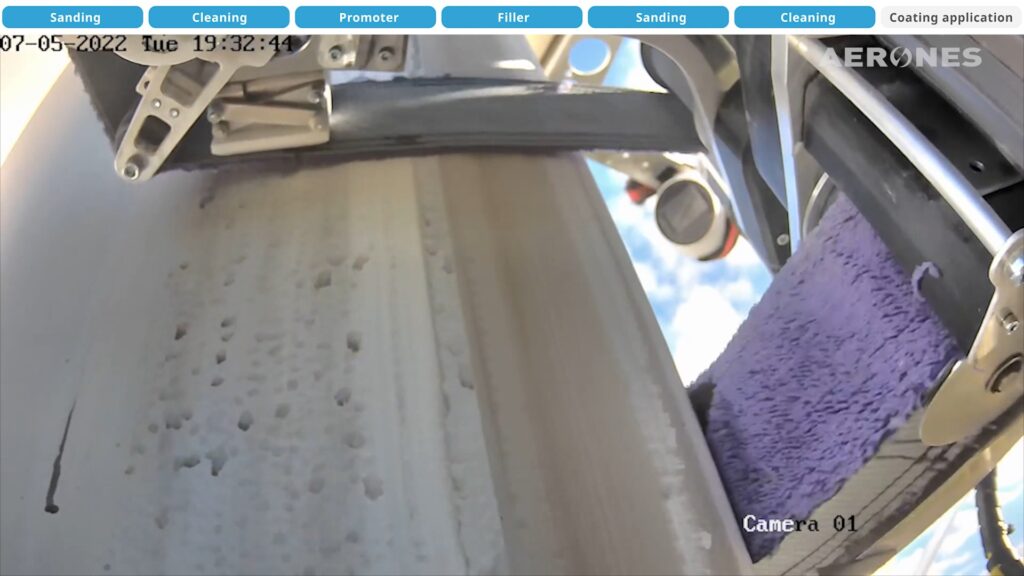

The foundation of the Aerones Wind Turbine Leading Edge Repair Robot is the modular toolkit. It’s a base platform that is controlled in vertical and horizontal space by a winch system. We can attach different robotic arms designed for various maintenance and inspection services. For blade repair services we have developed – leading edge surface sanding and cleaning, filler solution application, 3M protective tape removal, promoter and leading edge protection coating robot. There are more innovative repair solutions in the pipeline with a planned launch in 2023.

Wind Turbine Blade Leading Edge Repair Robot in Action

The results are remarkable. The robot can remove the old 3M tape or prepare the eroded surface by sanding and cleaning. The robot applies the promoter solution, applies the filler evenly on the prepared area of the eroded blade, and gets a perfect protective coating layer. The aerodynamics of the wind turbine blade are improved and the structural integrity is renewed. This causes significant AEP improvements, which leads to an increase in profits because of more electricity generated.

The wind industry must embrace new technology to maintain wind assets worldwide. As turbines and their blades become larger, they are harder to service with conventional methods, leading to larger downtime of turbines. With electricity prices increasing, each hour of a turbine out of operations is becoming more and more expensive. Our approach enhances the work of technicians, makes the services more efficient and decreases downtime.

Contact Aerones today to receive a price quote and a tailored repair operations plan for your wind assets.