High Voltage Gap Tester for WTG LPS Trouble-

Shooting

Right now most conductivity tests for wind turbine (WTG) blades are performed via Rope Access: only the blade is measured, from the root of the blade to the receptors. When deploying Aerones robotic technology to do LPS measurements we use long wires to complete a full circuit test in order to check whether, in case of a lightning strike, the charge will actually be properly grounded.

Performing the full circuit test also allows us to find where the WTG LPS system has missing connections; i.e., between the hub and the nacelle, the nacelle and the tower, etc.

If the wind turbine has spark gaps, rolling lightning conductors, or carbon brushes, we create a shunt, i.e., a bridge, between these gaps.

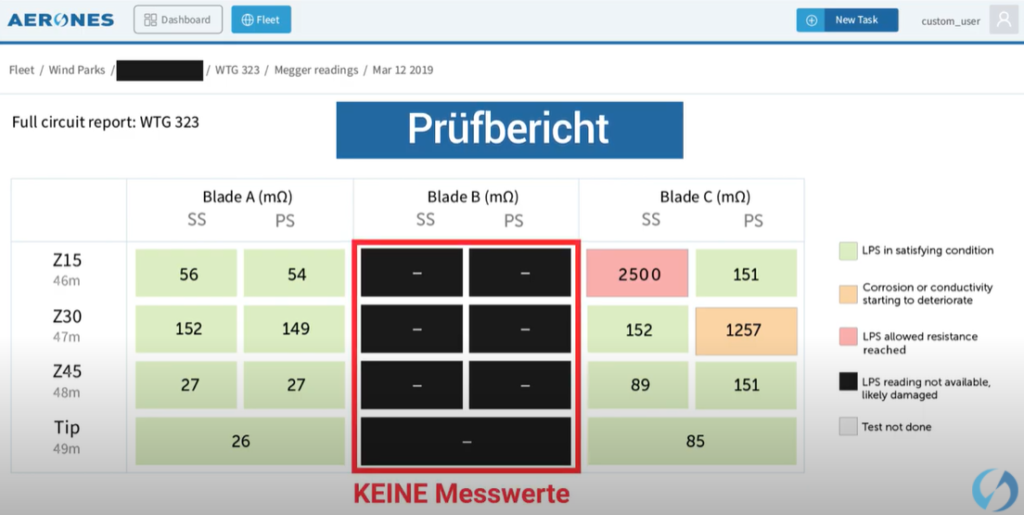

Here’s how our LPS inspection reports look like. We show the exact measurement of resistance for each receptor.

From our experience, there are many cases with no readings for the entire WTG blade. In such cases, we can do troubleshooting to locate the cause of the problem within the LPS.

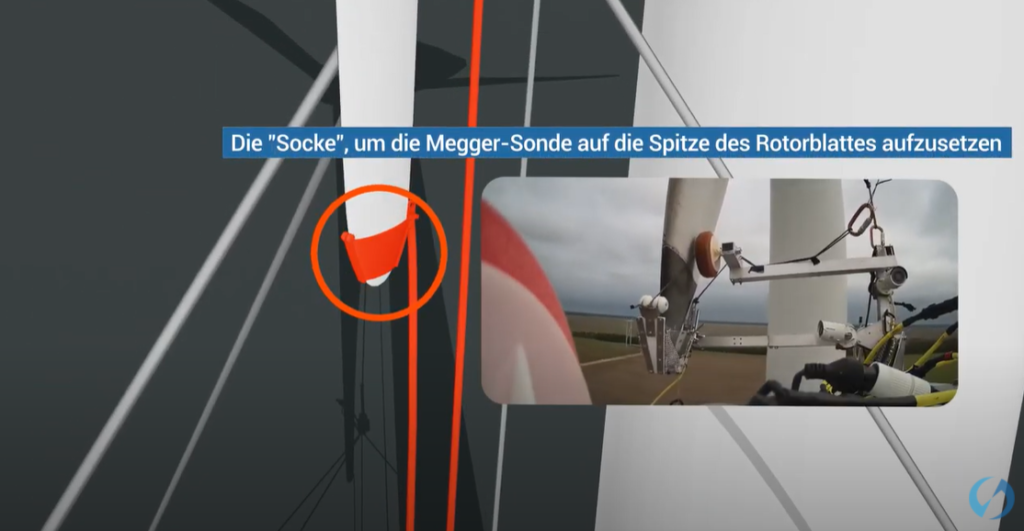

The first type of troubleshooting is to measure from the tip of the WTG blade to each receptor: we put one end of the Megger probe on the tip of the blade (the equipment we use we call a “sock”) whereas the other end of the probe the robot will bring to each receptor. There is a special kind of a “sock” for metallic blade tips as well as for blade tips with a receptor. In both cases, we can measure from tip to each of the receptors.

The other type of troubleshooting is to do the measurements from the WTG blade root to each receptor. We find that in most cases, the problem is somewhere between the last receptor and the root of the blade. The most common situation would be a broken wire or some issue within the lighting register box.

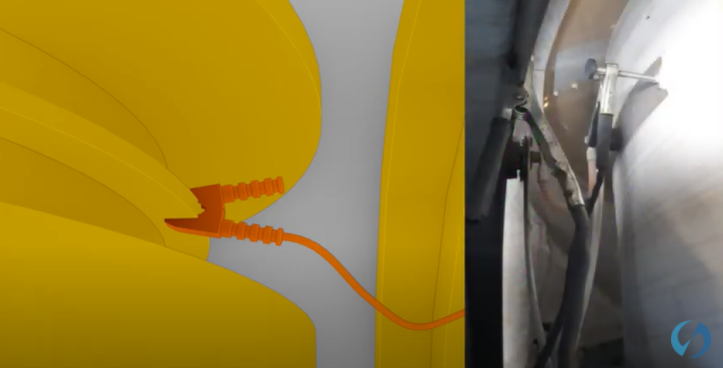

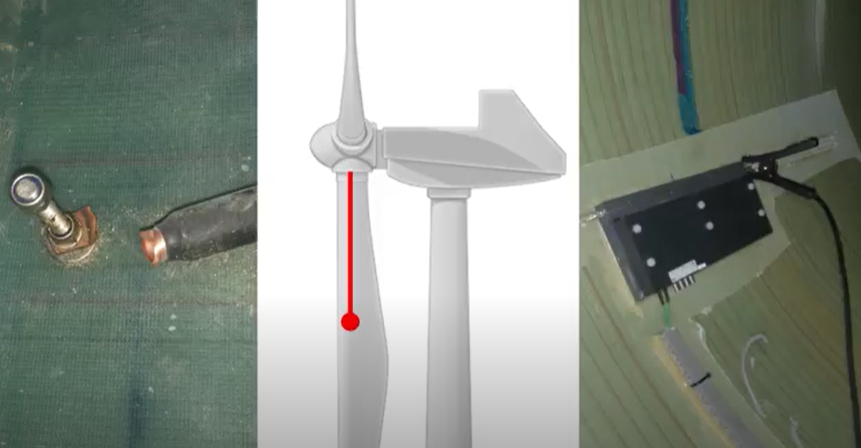

For the kind of cases where creepage problems, broken wires, or gaps exist, which usually form over time due to changes in temperature, different material expansion coefficients, mechanical damage, oxidation, or other reasons, here at Aerones, we have developed special equipment to test continuity within the LPS where classical measuring methods do not work: normally, low resistance Ohm-meters, with the measurement range up to 2 kΩ, are used. If there’s a spark gap in the LPS, the resistance can go above a 100 kΩ (and even MΩ) range.

The High Voltage Gap Tester generates shots of high voltage pulses to overcome the dielectric strength of the material between the conductors. This way we have the opportunity to adjust the output voltage by changing the distance between etalon electrodes, and by doing so we can determine how big the gap is within the LPS.

We create the spark, which will always travel through the shortest gap. If, for example, in the WTG blade the gap between two wires of the conductor will be 1 cm and in our test equipment 2 cm, the spark will jump through the wire in the blade.

If the gap in the blade is, for example, 2 cm and on the ground 1.9 cm, the spark will jump through the gap into the ground.

By performing this kind of test, it is not possible to damage anything within the WTG. For comparison: the voltage level for lightning strikes varies within the range of 10 to 120 MV. We use pulses of 100 kV: hundreds of times smaller than the lightning strike.