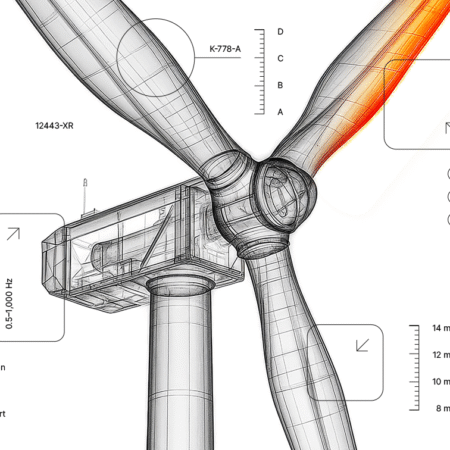

Fastest Leading Edge Cleaning and Ice-Phobic Coating

The new modular robotic tool base we launched this year has enabled us to apply new innovations to our service family much more quickly. Hence, we are happy to show you the new generation wind turbine blade leading edge brush and its combination with our leading edge ice-phobic coating robot.

Our leading edge brush robot tool hand cleans the blade surface sparkling clean. With high-quality brushes and a biodegradable detergent, we can clean the wind turbine blade’s leading edge in no more than 20 minutes. Clean of bugs, dirt, algae, oil, and other contaminants before performing repairs or applying coating on the leading edge.

And we’ve recently tested this approach together with our ice-phobic coating application robot. The results are perfect. We used the same robotic tool base and switched from brushes to the painting tool arm.

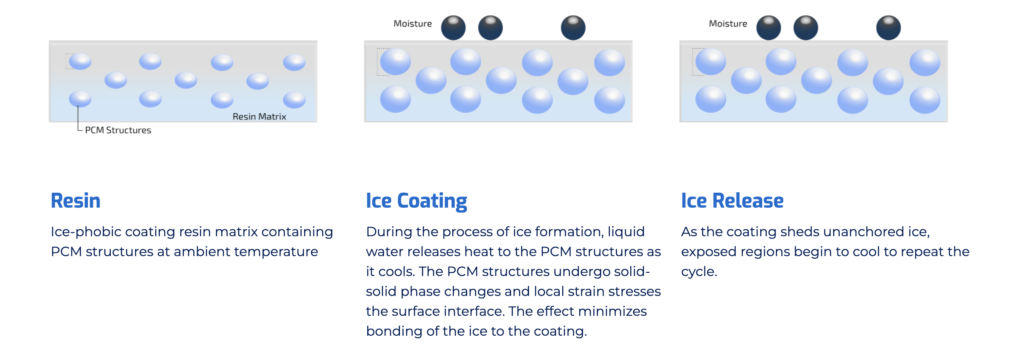

The coating process is seamlessly quick, as well. The robot can operate and coat the blade at a speed of 6 meters per minute. This results in perfectly coated blades in 4-6 hours. Protect your blades from freezing. By applying a high-quality coating, wind asset managers can avoid ice adhesion at freezing temperatures.

Ice buildup on wind turbines causes a variety of problems: reduction of power production, overloading because of delayed stall, increased fatigue of components, and risk of ice throw. This has a large effect on annual energy production.

Our robots can work at higher wind speeds and lower temperatures. Don’t lose potential revenue and be prepared for the winter!