See what hurts

your blades

before it hurts your business

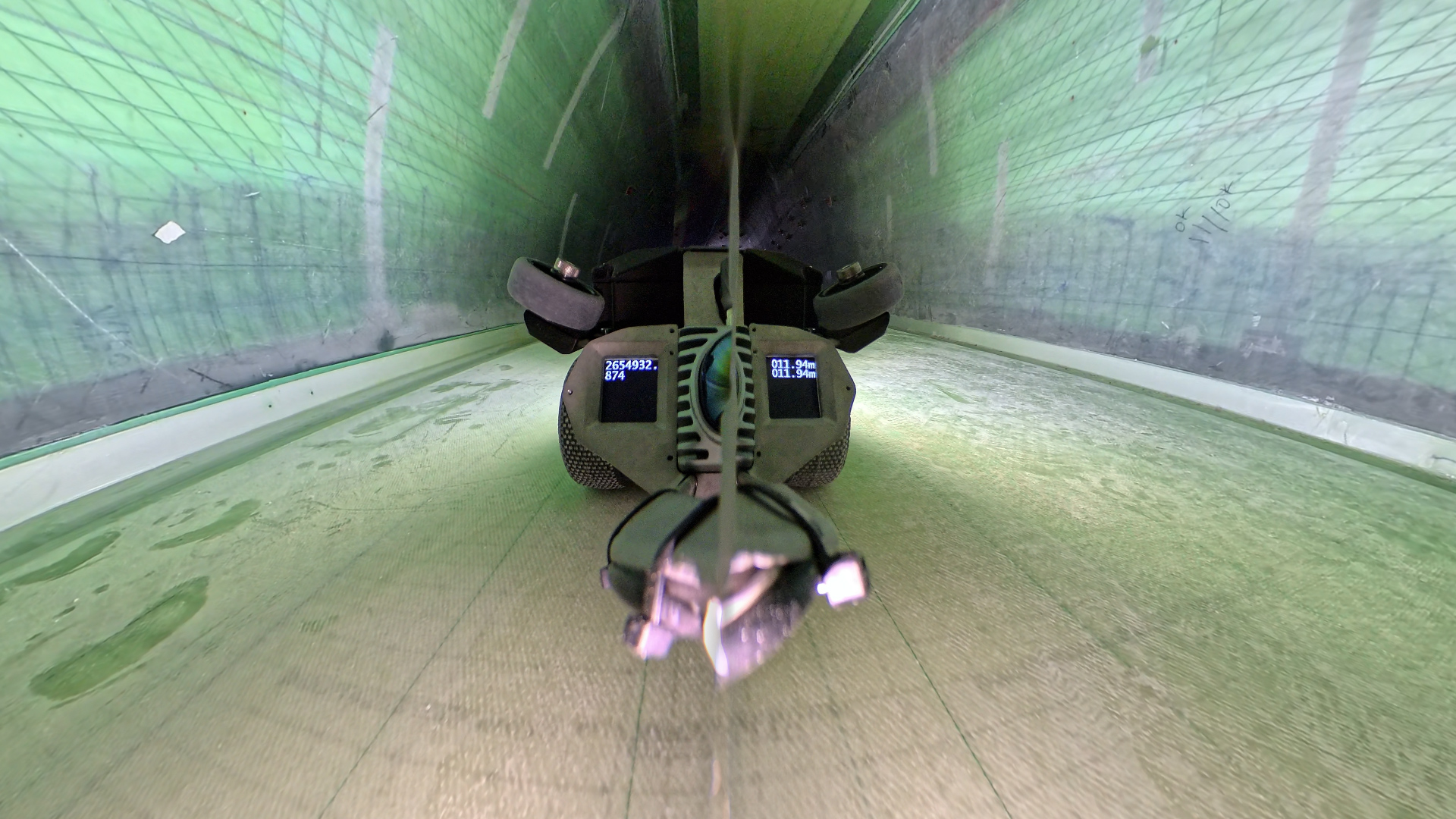

Blade internal inspection

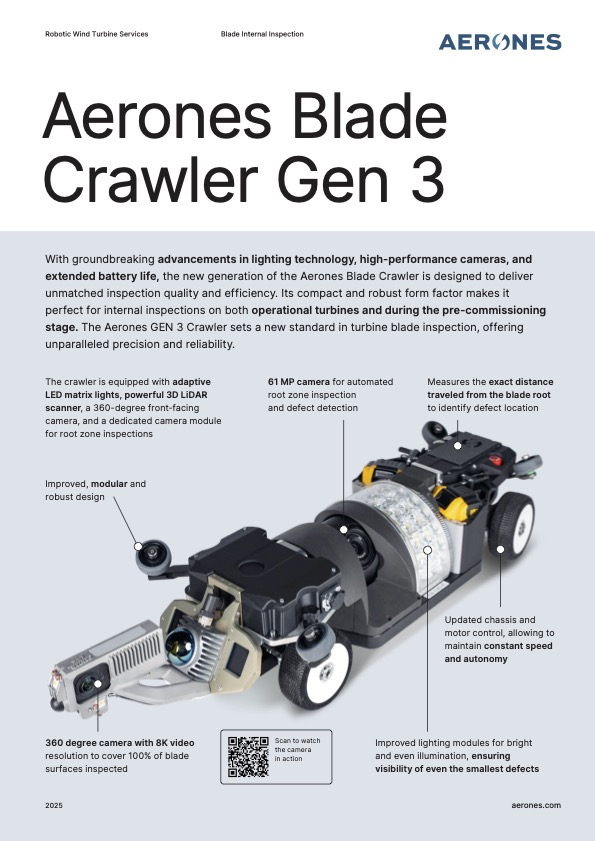

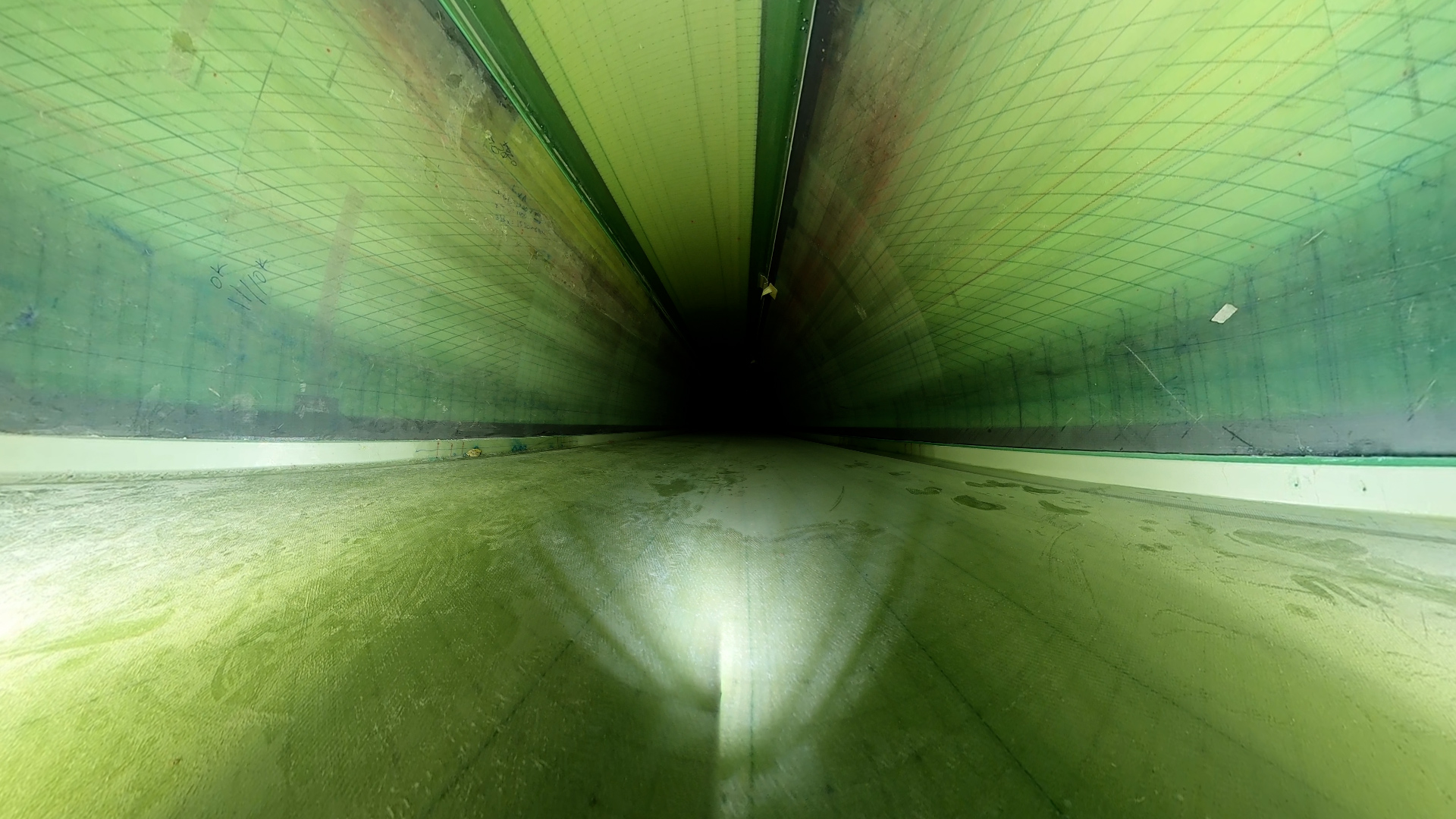

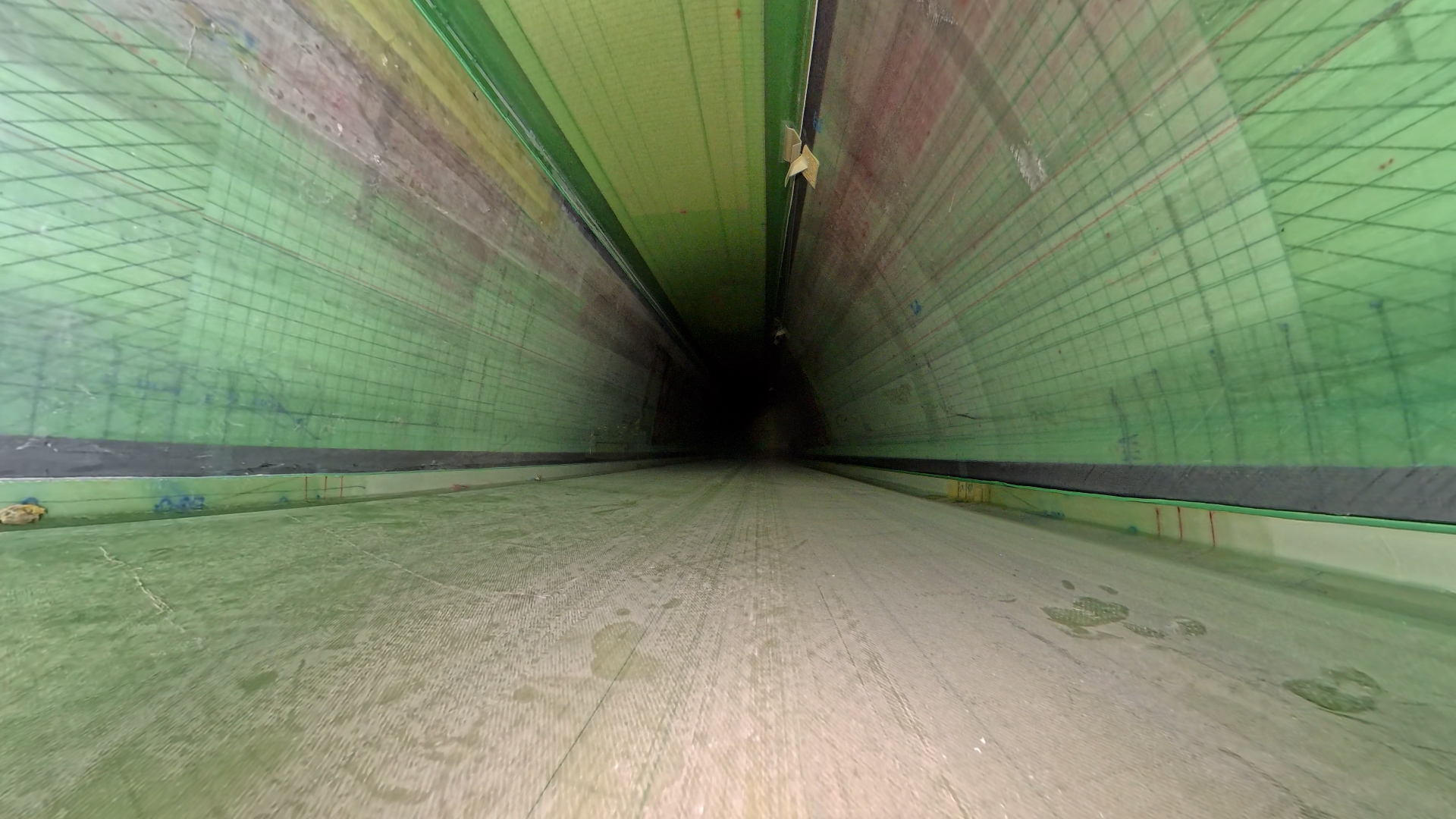

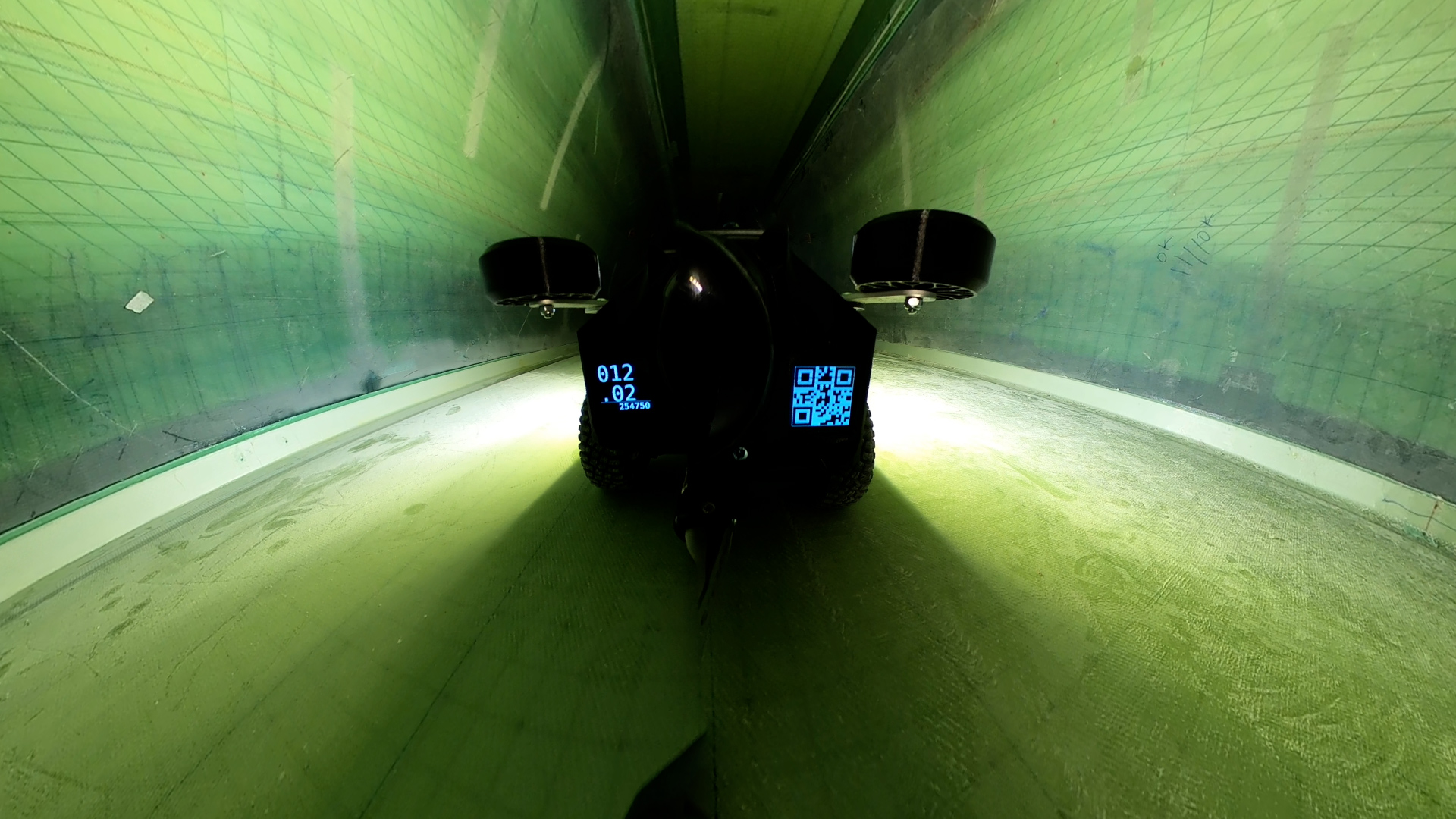

Our advanced wind turbine blade crawler technology features adaptive LED matrix lights, a powerful 3D LiDAR scanner, a 360-degree 8K camera, and a new 61MP camera for root zone inspection and defect detection. Designed for high-quality internal inspections, this crawler delivers efficiency and reliability, outperforming the competition and surpassing traditional inspection methods.

Technology benefits

Precision

3D LiDAR and 61 MP camera deliver ultra-detailed blade analysis

Full coverage

360° 8K video ensures complete surface visibility

Brightness

Powerful adaptive LED’s adjust brightness for even and well-lit lighting throughout the blade

Long battery life

Hot-swap high-capacity batteries for long, uninterrupted operations.

Multifunctional

Ideal for factory inspections, post-transportation inspections and pre-commissioning stages as well as on operational turbines.

Data access

All internal and external blade inspection data combined in one platform for smarter, faster maintenance decisions

Technical parameters

How it works

Gen 2 vs. Gen 3 capabilities

Receive a special offer before it is too late!

Together with our Visual Inspection Studio, Crawler is a truly powerful inspection solution – bringing together high-quality data collection and intuitive visual analysis in one seamless ecosystem.

Watch our webinar