Robotic Wind Turbine Blade Cleaning

- Home

- Our Services

- Cleaning

- Blade Cleaning

Cleaning

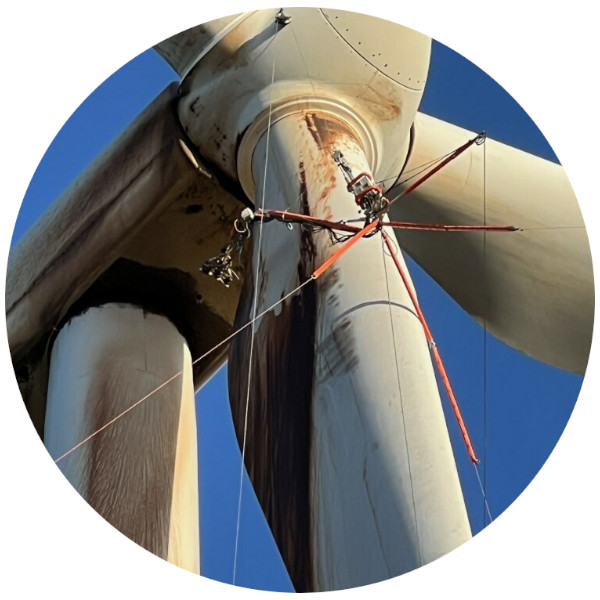

Cleaning by robots

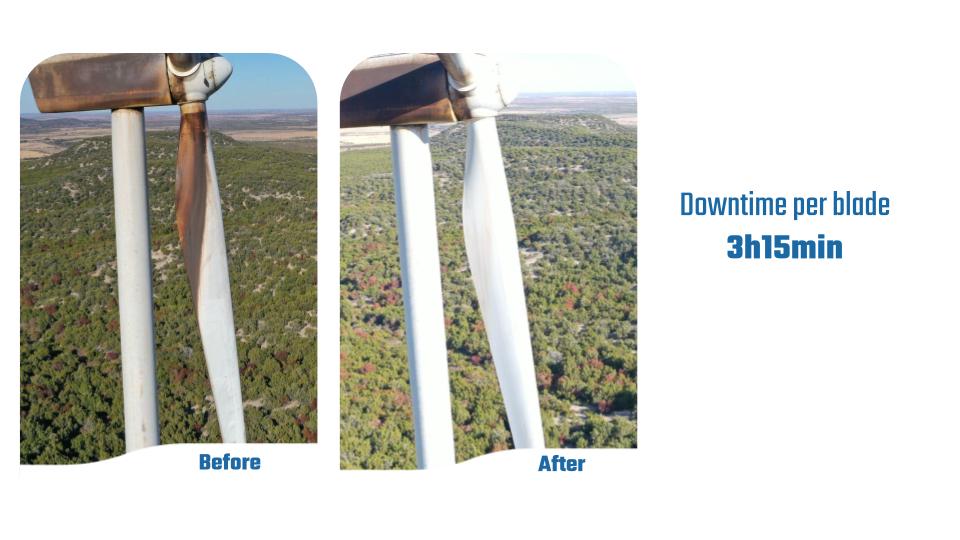

In time, depending on the surrounding environment, a layer of insects and dirt may appear on the wind turbine blade in operation – in particular on the blade leading edge. This creates a rough surface that badly influences the blade's effectiveness.

Thus, a regular blade cleaning is recommended to renew the airflow efficiency to factory quality. The blade cleaning robot also performs cleaning before leading edge repair or coating services.

Time Efficient Robotic System

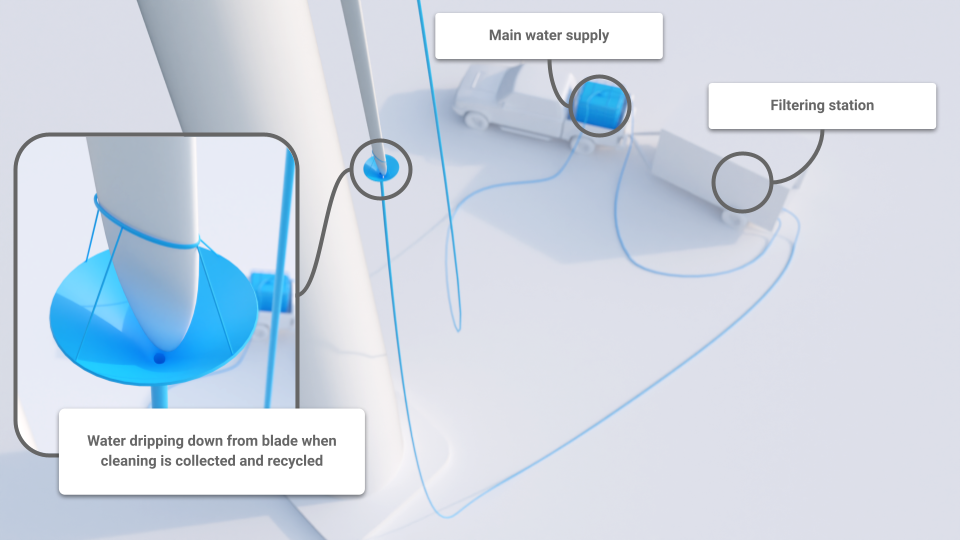

Three brush system with biodegradable soap supply allows for efficient removal. On average 10 hours are required to clean all 3 blades of one turbine unless the blades are extremely dirty and need additional cleaning.

Contact us

Schedule a presentation, receive a detailed information about the services or request a price quote

Exceptional Performance in Harsh Environments

Dirt reduces the blades' aerodynamics and disrupts the airflow, forcing the turbine to work harder reducing AEP.

There may be even a tiny amount of dust, oil, or debris that settles in the seams on the blade. Wherever it collects, it can hold water, and eventually, seep into materials. Ice accumulation is also a big problem induced by surface roughness.

But even before that happens, the blades’ weight increases (due to retained moisture), forcing the turbine to work harder to produce energy.

Contacts

EU: Vestienas 32, Riga,

Latvia, LV-1035,

US: 105 N 1st St #429 PMB 22980

San Jose, CA 95103

Phone: +371 2809 0999

Phone: +1 669 213 80 50

Email: [email protected]